Why Test HVAC Water?

Corrosive conditions, scaling, and biofilm formation impair heat exchange and force systems to work harder, raising energy bills.

Cooling towers and open-loop HVAC systems can harbor Legionella and other microbes, creating serious health risks if not properly monitored. Our CDC ELITE–certified Legionella testing and ASSE 12080–qualified water safety expertise help you detect contamination early and maintain full ASHRAE 188 compliance for safe and efficient system operation.

Corrosion weakens pipes, valves, and heat exchangers. Scale deposits lower system efficiency and can lead to costly repairs or early equipment replacement.

Many jurisdictions and guidelines, such as ASHRAE 188, call for periodic Legionella testing in HVAC systems. Our regulatory compliance services help ensure alignment with local and national health standards.

Trusted Standards & Certifications

We maintain the highest standards in environmental compliance and sustainability. Our certifications demonstrate our commitment to responsible practices and regulatory excellence.

Key Testing Parameters & What They Reveal

Why Test:

Proper pH balance is critical to prevent corrosion and scaling. Alkalinity levels guide water treatment decisions, ensuring optimal chemical dosing to maintain stable conditions.

Why Test:

High TDS can indicate excessive mineral content, which leads to scale buildup, reducing heat transfer efficiency. Conductivity measurements track the overall ionic load and help determine when blowdown or treatment adjustments are needed.

Why Test:

Hard water minerals precipitate as scale on heat exchanger surfaces, increasing energy consumption and wear on equipment. Monitoring hardness supports preventative measures like softening or anti-scale treatments.

Why Test:

Elevated metal concentrations suggest corrosion of pipes or equipment. Early detection enables targeted corrosion inhibition programs, extending the life of costly infrastructure.

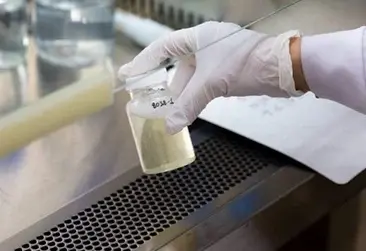

Why Test:

Biofilms and bacterial growth reduce heat exchange, raise health risks, and promote corrosion. Routine microbial testing and Legionella screening help maintain safe and hygienic conditions.

Why Test:

Many HVAC systems use chemical treatments—corrosion inhibitors, scale inhibitors, and biocides—to maintain water quality. Measuring their residual levels confirms proper dosing, ensuring conditions remain stable and contamination is minimized.

Real-World Applications

Maintain comfort and energy efficiency by preventing scale buildup in chillers and ensuring that cooling tower water meets recommended microbial standards.

Hospitals and clinics require Legionella testing and corrosion control to protect patients. Routine microbial screening minimizes risk and supports safety and regulatory compliance.

Improve heat transfer efficiency and system reliability by optimizing the chemical balance in high-stakes cooling systems that protect sensitive equipment from overheating.

Preserve expensive mechanical components by controlling corrosion and scaling in steam and hot water loops critical for process heating and climate control.

From Data to Actionable Insights

At PITS Environmental, we don’t just provide numbers, we interpret results in the context of your system’s design, operating conditions, and regulatory obligations. We help you:

Adjust chemical dosing or filtration systems to maintain stable water chemistry that prevents corrosion, scaling, and microbial growth.

Use test data to anticipate issues before they become expensive problems, scheduling cleaning, flushing, or component replacements proactively.

Monitor water quality before and after introducing new equipment or changing chemical regimens to confirm improvements in efficiency and longevity.

Quality Assurance & Expertise

Our laboratory adheres to industry-recognized standards and undergoes regular proficiency testing to ensure accurate, reliable results.

Our team of water treatment specialists, chemists, and microbiologists partners with your facilities or maintenance staff to design testing schedules, interpret findings, and recommend improvements tailored to your systems.

As buildings grow smarter and more interconnected, we stay updated on emerging guidelines, advanced corrosion inhibitors, and innovative water treatment methods, helping you adapt to changing technologies and best practices.