The Toshiba X300 HDD is a high-performance internal hard drive widely chosen by professionals in creative industries. With its large capacity and speed, it’s particularly favored by graphic designers, 3D modelers, and digital content creators. However, like all mechanical hard drives, it remains vulnerable to physical damage.

In this case study, we highlight how PITS Data Recovery successfully performed a Toshiba drive recovery for a graphic designer who lost access to critical mold design samples after a drop incident.

Incident Overview: Physical Damage Leads to Data Inaccessibility

The incident occurred when the designer’s laptop was accidentally knocked off a desk. Although the laptop casing absorbed some of the impact, the internal Toshiba X300 4TB hard drive suffered mechanical damage and stopped responding. The drive contained years of work including unique design files, renderings, and sample molds.

The client initially sought help from a local computer repair shop. The technicians attempted to clone the drive using disk imaging tools, but the clone was unreadable. The partition structure appeared corrupted, and the files remained inaccessible.

Seeking Professional Toshiba Drive Recovery Services

Realizing that the data was irreplaceable, the client contacted our team at PITS Data Recovery. Known for our advanced facilities and experience in Toshiba HDD recovery, we arranged expedited shipping of the damaged drive to our recovery lab for evaluation.

Your Data Security Is Our Priority

Data privacy isn’t optional. It’s our commitment. Our secure recovery process ensures your sensitive information stays protected from start to finish.

HIPAA Compliant

GDPR Compliant

Secure Facility

NDA Available

Trust in certified security. Start your recovery today! Call Now: 888.611.0737

Step 1: Evaluation of the Toshiba X300 4TB Drive

Upon arrival, the drive was registered, labeled, and assigned a case ID. Our evaluation process involved:

External Inspection

We first checked the drive housing for dents, scratches, or shock marks that might indicate platter impact or motor misalignment.

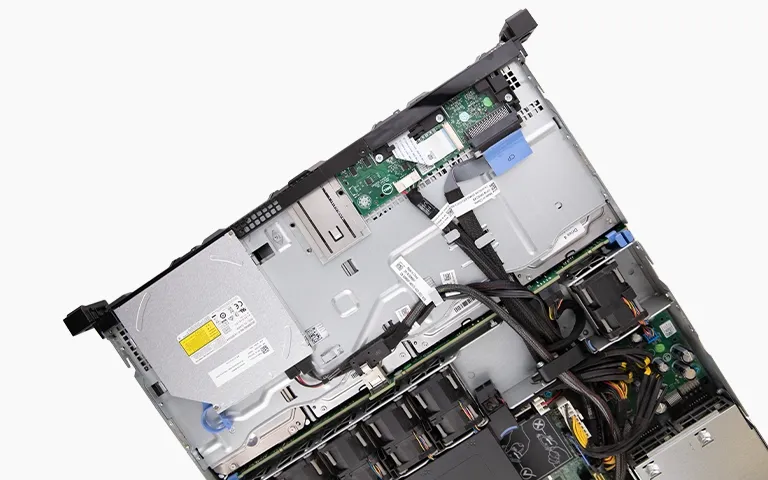

Cleanroom Disassembly

The drive was disassembled in our ISO Class 10 Certified Cleanroom, which allows us to open storage devices without the risk of dust contamination.

Diagnostic Testing

Using industry-leading tools, we assessed key components such as:

- Read/write head assembly

- Spindle motor alignment

- Platter surface integrity

- Firmware condition

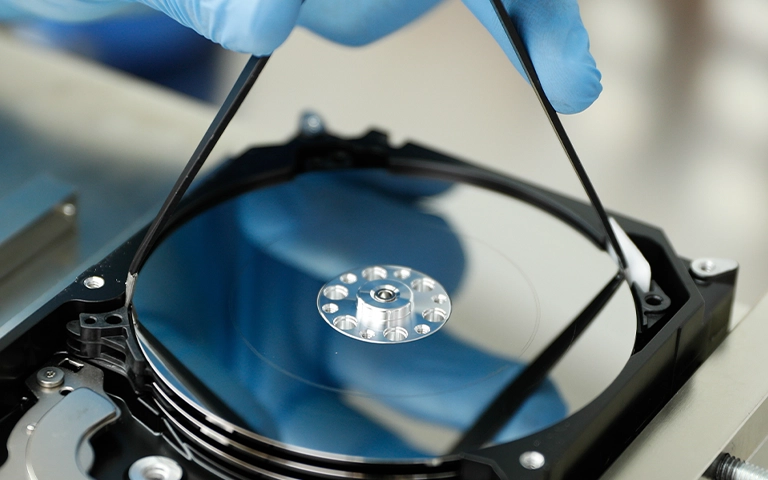

The diagnosis confirmed that the read/write heads were damaged, preventing the drive from accessing stored data.

Step 2: Advanced Toshiba HDD Recovery Process

Contaminant Removal

We began by gently cleaning the platter surface using anti-static, lint-free methods to ensure no debris could interfere with recovery.

Precision Head Replacement

Our engineers sourced a matching donor head assembly from our extensive parts inventory. This highly technical process involves:

- Extracting the damaged head assembly without platter contact

- Installing the donor heads using head-combs and MHA pullers

- Aligning the heads with nanometer precision

Drive Recalibration and Function Testing

Once the new heads were installed, we recalibrated the drive and ran diagnostic tests to ensure stable read access. The drive spun up successfully and passed preliminary imaging tests.

Step 3: Data Extraction and Structure Reconstruction

With the drive operational, we used sector-by-sector imaging to create a full copy of the disk contents. During this phase:

- Damaged sectors were isolated and skipped or retried using adaptive read settings

- A complete disk image was assembled to avoid working on the original drive

- File system corruption was analyzed and repaired at the logical layer

We recovered the full folder structure, including deeply nested project files and proprietary design software formats.

Step 4: Verification with the Client

To ensure all files were intact, we conducted a live file verification session with the client. The designer reviewed the recovered data via remote preview, confirming that:

- All critical design molds were present

- File integrity and naming structure were preserved

- No corruption was found in project files

Get a Free Consultation.

Our recovery experts are ready to assess your device and guide you through the safest path to recovery. Fill out the form to get started.

"*" indicates required fields

Final Delivery and Client Education

We securely transferred the recovered data to a new 4TB external hard drive and shipped it to the client with tracking and encryption. After the successful recovery, we provided guidance on:

- Creating regular versioned backups

- Using cloud sync tools for active projects

- Implementing impact-resistant storage enclosures

This case reinforced the importance of consulting professionals for high-stakes recoveries. The earlier failed clone attempt by the repair shop could have worsened platter damage had it not been caught in time.

Why Trust PITS for Toshiba Drive Recovery?

At PITS Data Recovery Services, we offer:

- Decades of experience with Toshiba HDD recovery

- Cleanroom-equipped labs for head and platter repairs

- A massive inventory of Toshiba donor parts

- Confidential handling of sensitive and creative assets

- Verified success in recovering critical files after mechanical failure

Whether your Toshiba drive is clicking, not spinning, or completely undetectable, our team is prepared to assist with reliable and efficient solutions.

Need Help? Contact Us for Toshiba X300 Hard Drive Recovery

If your Toshiba hard drive has suffered physical damage or has become inaccessible, don’t delay. Contact our expert recovery engineers for fast, professional assistance.

What Our Customers Are Saying

Don't Let Data Loss Ruin Your Business

Minimize business disruption. We retrieve lost data fast, so you can focus on what matters.