When a business owner walked into our lab with a lifeless Vector 256GB SSD, they were on the edge of losing years of sensitive business documents, accounting data, and engineering files. The SSD had suddenly gone completely dark after a power surge caused by a thunderstorm and their entire operation hung in the balance.

This is the story of how we used advanced diagnostics voltage injection, thermal imaging, cold spray, and chip-off recovery to bring the data back from what looked like a hopeless case.

The Beginning: A Dead Drive and Desperate Call

The client, an architectural design firm, had relied heavily on a single Vector SSD inside their main workstation. It had been stable for years fast, silent, and flawless. But after a lightning strike tripped their breaker panel, the machine never booted again.

Their IT team tried everything: swapping cables, different ports, different computers. No BIOS detection. No activity lights. No sound. Just a stone-cold SSD.

That’s when they found us.

Initial Assessment: Total Power Loss, No Detection

Once we received the drive, our engineers began with basic testing:

- No power draw from the SSD

- No detection via SATA interface

- Zero response on any platform

Something deep inside the PCB had failed and it smelled like a short circuit.

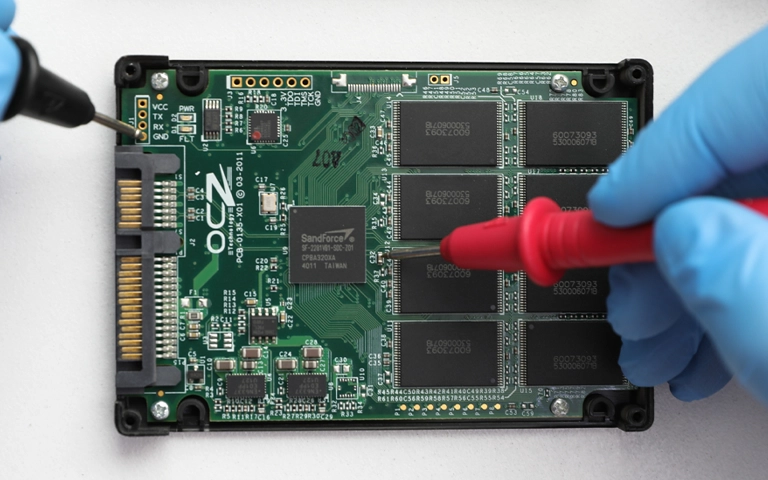

Voltage Injection: Finding the Electrical Fault

We started by isolating the power rail and using a low-voltage, high-current bench supply to inject 3.3V into the board. The current shot up an immediate red flag that a component was internally shorted.

This method is the gold standard in professional diagnostics. A board drawing more than 1A at low voltage usually has a capacitor or power IC turned into a fuse.

But the board was too small and dense to spot anything visibly burnt.

Get a Free Consultation.

Our recovery experts are ready to assess your device and guide you through the safest path to recovery. Fill out the form to get started.

"*" indicates required fields

Thermal Imaging: Unmasking the Hotspot

Next, we used a FLIR thermal camera to visualize what our eyes couldn’t see.

Within seconds of applying voltage, one tiny capacitor near the SSD’s controller glowed bright white on the thermal view reaching over 150°F. That was our culprit.

A shorted ceramic capacitor had failed silently, but its microscopic internal crack turned it into a heater.

Super-Cooling & Microscopic Confirmation

To confirm, we sprayed the board with cold spray, instantly frosting the entire PCB to below -40°C. Then, under a microscope, we reapplied power.

As expected, that same capacitor melted the frost in seconds pinpointing the fault with absolute certainty.

This method, often called freeze-and-heat tracing, is used in high-end electronics repair labs, and it’s one of the safest ways to visually identify shorts without damaging other components.

The First Fix: Removing the Short

We carefully desoldered the faulty capacitor using hot air and anti-static tweezers, cleaning the pad and checking the rail again.

- ✅ Current draw dropped to normal levels

- ✅ Voltage passed through the board

- ❌ But still… no detection.

The drive’s controller had been damaged too. We had restored power but not functionality.

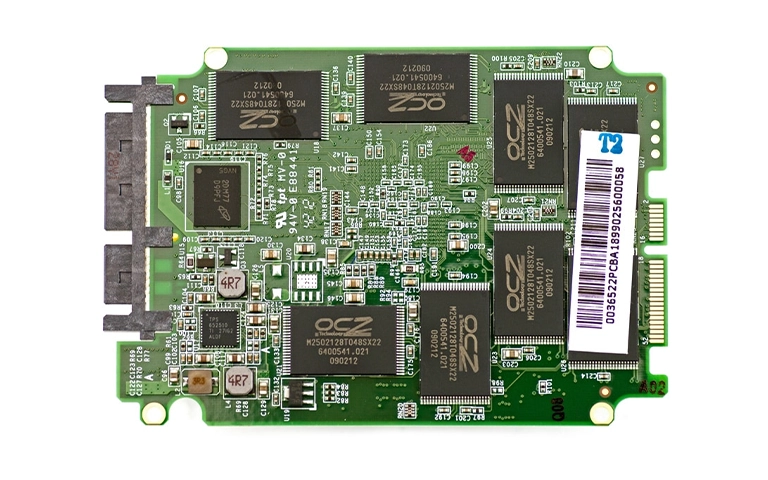

Next Step: Chip-Off Data Recovery

With the SSD’s logic board unfixable, we moved to chip-off recovery:

- Desoldering NAND Chips: Using precise temperature control, we removed each memory chip from the PCB.

- Dumping Raw Data: We used a professional NAND reader to extract binary dumps from each chip.

- Firmware Emulation & FTL Mapping: Vector SSDs use complex firmware structures and translation layers (FTL). We reconstructed these manually using our proprietary tools and firmware database.

- Logical File System Rebuild: Once raw data was organized, we ran a full volume scan and file structure rebuild.

The Result: A Full Recovery, and a Grateful Client

The client’s most crucial folders CAD drawings, financial records, and tax documentation were recovered 100% intact.

In total, we successfully retrieved over 98% of the SSD’s entire data, and delivered it on a new encrypted external drive within 5 business days.

The client’s feedback?

“We thought we lost everything. Your team didn’t just save files you saved our business.”

Your Data Security Is Our Priority

Data privacy isn’t optional. It’s our commitment. Our secure recovery process ensures your sensitive information stays protected from start to finish.

Trust in certified security. Start your recovery today! Call Now: 888.611.0737

Lessons from This Recovery

This case reinforces a few important lessons for all SSD users, especially those seeking OCZ SSD data recovery.

Even SSDs Can Fail Catastrophically

They’re fast, but not indestructible. Power surges, faulty cables, or even humidity can trigger short circuits.

Professional Tools Matter

Without voltage injection, thermal imaging, cold spray, and chip-off tools, recovery would’ve been impossible.

Backups Are Still the Best Defense

No matter how reliable the device, always keep redundant and offsite backups of critical data.

Signs Your SSD May Be Shorted

- Drive not detected in BIOS or OS

- Overheating without data activity

- Motherboard shuts off when SSD is plugged in

- No voltage reading across SATA power pins

If You Suspect SSD Failure Act Fast

Stop using the drive. Don’t plug it into adapters or other machines. Every second of powered use risks further damage. For SSD data recovery, immediate action is critical to prevent permanent loss.

- Call our lab at 888.611.0737

- Or visit: www.pitsdatarecovery.com

Don't Let Data Loss Ruin Your Business

Minimize business disruption. We retrieve lost data fast, so you can focus on what matters.